- Home

- Services

- EPOXY FLOORING

- POLYURETHANE FLOORING

- DI-ELECRIC FLOORING

- ANTI-STATIC EPOXY FLOORING

- ESD FLOORING

- ACCESS FLOORS

- CAR PARK DECK FLOORING

- CLEAN ROOM FLOORING

- HEAVY DUTY EPOXY FLOORING

- HYGIENE FLOORING

- SELF LEVELLING EPOXY FLOORING

- COLD STORAGE FLOORING

- ACID RESISTANCE FLOORING

- CAR PARK COATING

- EXPANSION JOINTS

- Projects

- Blog

- About Us

- Contact

What Is Heavy Duty Epoxy Flooring?

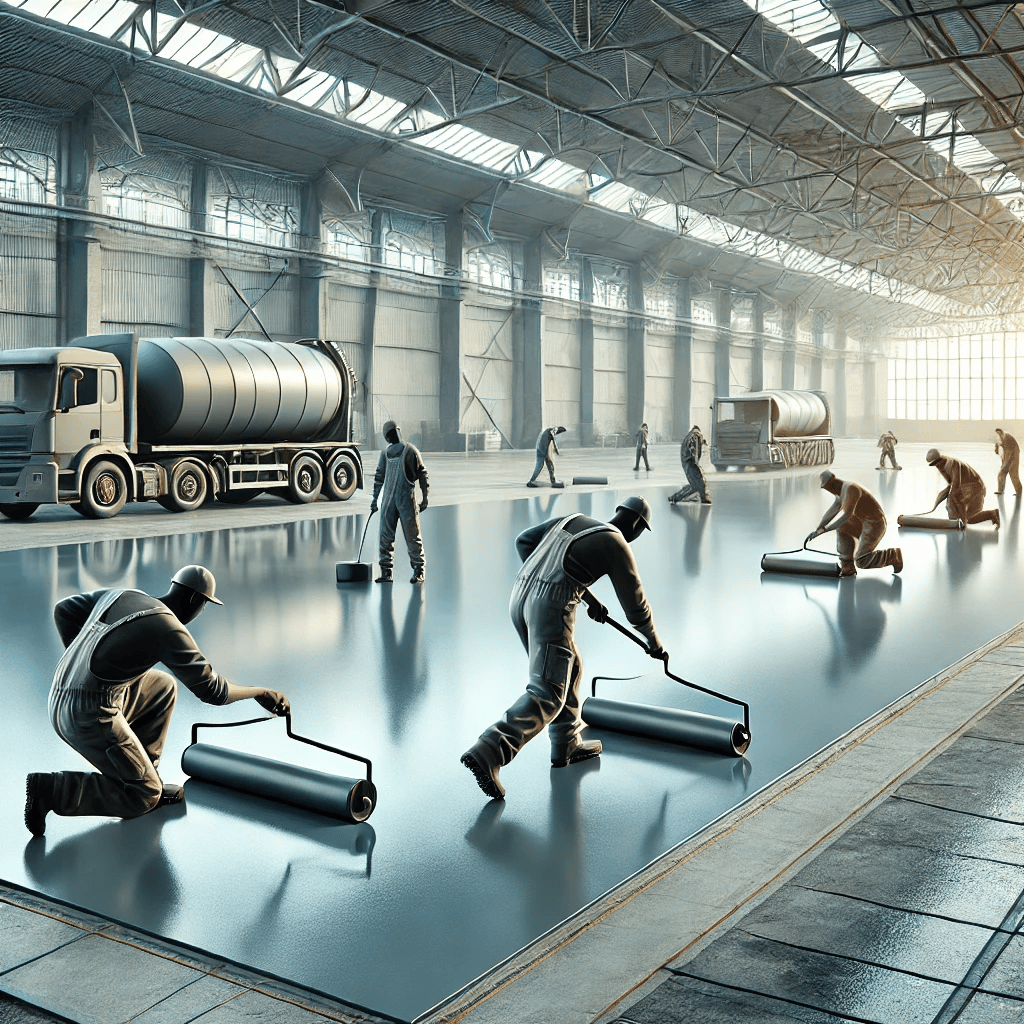

Heavy Duty Epoxy Flooring: The Ultimate Solution for Durability and Performance

When it comes to flooring in high-traffic, industrial, or commercial spaces, heavy-duty epoxy flooring stands out as a superior option. Whether you’re looking to protect your garage from vehicle wear, install a durable surface in a warehouse, or enhance the functionality of a showroom, epoxy flooring offers unmatched strength and versatility.

What Is Heavy Duty Epoxy Flooring?

Heavy-duty epoxy flooring is a type of resinous flooring system that’s designed to provide a strong, durable, and long-lasting surface for areas that experience heavy use. It’s created by combining two main components: an epoxy resin and a hardener. When mixed, these chemicals form a solid, tough, and seamless surface that adheres firmly to concrete or other substrates.

The “heavy-duty” formulation refers to the ability of the flooring to handle tough conditions such as high foot traffic, heavy machinery, chemical exposure, and even extreme temperatures. This makes it ideal for industries and environments where floor surfaces are subjected to constant wear and tear.

Benefits of Heavy Duty Epoxy Flooring

Durability

One of the primary reasons to choose epoxy flooring is its incredible durability. This flooring type can withstand the impact of heavy machinery, vehicle traffic, and more without cracking or wearing down quickly. The epoxy bonds strongly to the concrete surface beneath it, ensuring that the flooring stays intact and performs reliably for years.

Chemical Resistance

Epoxy flooring is highly resistant to a range of chemicals, including oils, solvents, and cleaning agents. This makes it perfect for garages, laboratories, factories, and warehouses where spills are common. With epoxy, you don’t have to worry about chemicals damaging or staining your floors.

Aesthetic Appeal

While epoxy is known for its toughness, it also offers a visually appealing finish. It can be customized with different colors, textures, and even decorative flakes, making it an attractive addition to any space. Whether you’re looking for a sleek, modern look or something more colorful and vibrant, epoxy can deliver.

Low Maintenance

Another major benefit of heavy-duty epoxy flooring is its low maintenance. It’s easy to clean—simply sweeping or mopping is usually enough to maintain its appearance. Since it’s resistant to staining and dirt doesn’t adhere to the surface easily, you won’t spend much time or money on upkeep.

Safety

Epoxy coatings can also include anti-slip additives, which help increase safety in high-traffic or wet environments. This is especially beneficial in areas such as factories, kitchens, and garages where spills and slippery conditions can create hazards.

Cost-Effective

While the initial installation of heavy-duty epoxy flooring might cost more than some other flooring options, its long lifespan, low maintenance, and ability to resist damage make it a cost-effective choice in the long run. You won’t have to replace or repair it often, and its durability ensures a high return on investment.

Ideal Applications for Heavy Duty Epoxy Flooring

Epoxy flooring is incredibly versatile and can be used in a wide range of environments, including:

Industrial Settings: Factories, warehouses, manufacturing plants, and distribution centers.

Commercial Spaces: Retail stores, showrooms, and office buildings.

Residential Garages: Homeowners looking to protect their floors from vehicle traffic, chemicals, and spills.

Chemical and Laboratory Environments: Areas where resistance to harsh chemicals is critical.

Healthcare Facilities: Hospitals and clinics, where hygiene and easy maintenance are top priorities.

Installation Process

Proper installation of heavy-duty epoxy flooring is key to ensuring its long-lasting performance.

Surface Preparation

For epoxy to adhere properly, the surface must be clean, dry, and free from any contaminants. This may involve removing old coatings, filling cracks, and even grinding or shot-blasting the concrete to create a smooth, roughened texture for better bonding.

Priming

A primer is applied to the surface to help the epoxy bond better and prevent any peeling or delamination later on.

Epoxy Application

The epoxy resin and hardener are mixed according to manufacturer specifications. The mixture is then spread across the surface using rollers or squeegees. Depending on the system, multiple coats may be applied to ensure maximum strength and coverage.

Curing Time

The epoxy must cure for a certain period (usually 24-72 hours, depending on the temperature and thickness of the coating) before the surface can be used.

Maintenance and Longevity

Cleaning: Regular sweeping and mopping with mild detergent will help keep the surface clean. Steer clear of strong chemicals that may harm the finish.

Repairs: If the flooring becomes scratched or damaged, small repairs can be made by applying a new layer of epoxy over the affected area.

Re-coating: Over time, depending on the wear and tear, you may need to apply a fresh coat of epoxy to maintain its appearance and performance.

Have Any Question?

- +91 9962699888

- Sales@Chemcoats.com

- 19/10, Rangarajapuram 3rd Street, Netaji Nagar, West Jafferkhanpet, Chennai, Tamil Nadu 600083

- Sales@Chemcoats.com

- +91 9962699888